Key Features of a Single Board Computer Embedded in Smart Factory Applications

A robust single board computer (SBC) is a cornerstone of modern industrial applications, driving automation, robotics, machine health monitoring, wireless sensor networks, safety systems, asset tracking and networking.

Our SBCs are engineered for IoT integration, predictive maintenance and real-time data processing, offering the performance needed for edge computing and AI-driven quality control in smart factories. Built with futureproofing and wireless flexibility in mind, they are equipped to handle the demands of extreme environments while accelerating machine learning and AI operations.

Manufactured in the USA, our industrial-grade SBCs withstand extreme temperatures and rugged conditions, ensuring reliability and longevity. Powered by the NXP™ i.MX 8M Mini or Plus ARM® CPU, they offer customizable configurations and out-of-the-box evaluation kits for rapid deployment and faster time to market. Security is paramount, with features like TPM and secure boot protecting data and operations. Backed by over 10 years of product lifecycle support and Linux Ubuntu compatibility, Gateworks SBCs are the ideal choice for digital transformation and industrial IoT in smart manufacturing environments.

Futureproof Flexible Wireless Options

NXP™ i.MX 8M Mini or Plus ARM® Cortex Quad CPU

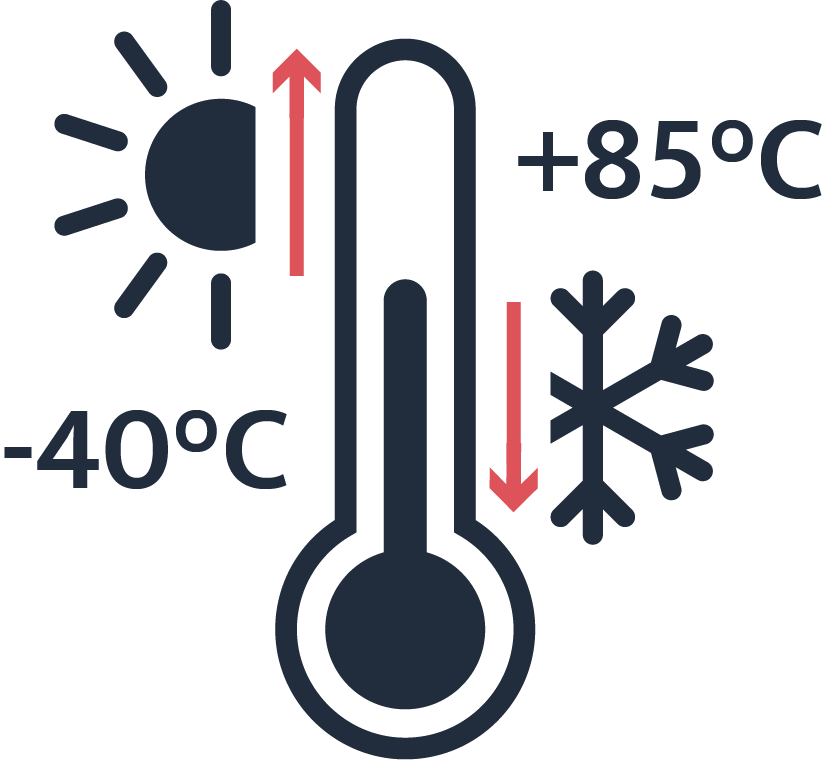

Industrial-Grade Operating Temperature

Security: TPM & Secure Boot

Linux Ubuntu BSP & Software Support

Made in the USA

Built-In NPU for Machine Learning

10+ Years Product Lifecycle

Out-of-the-box Evaluation Development Kits

Ruggedized for Shock & Vibe

GPIO, USB, CAN, RS232, RS485, SPI & I2C Interfaces

Proven Reliability & Quality Control

Customizable & Special Configurations

Accelerated Time to Market

Key Features of a Single Board Computer Embedded in Smart Factory Applications

A robust single board computer (SBC) is a cornerstone of modern industrial applications, driving automation, robotics, machine health monitoring, wireless sensor networks, safety systems, asset tracking and networking.

Our SBCs are engineered for IoT integration, predictive maintenance and real-time data processing, offering the performance needed for edge computing and AI-driven quality control in smart factories. Built with futureproofing and wireless flexibility in mind, they are equipped to handle the demands of extreme environments while accelerating machine learning and AI operations.

Manufactured in the USA, our industrial-grade SBCs withstand extreme temperatures and rugged conditions, ensuring reliability and longevity. Powered by the NXP™ i.MX 8M Mini or Plus ARM® CPU, they offer customizable configurations and out-of-the-box evaluation kits for rapid deployment and faster time to market. Security is paramount, with features like TPM and secure boot protecting data and operations. Backed by over 10 years of product lifecycle support and Linux Ubuntu compatibility, Gateworks SBCs are the ideal choice for digital transformation and industrial IoT in smart manufacturing environments.

AUTOMATION

Enhancing Efficiency Through Intelligent Automation on the Edge

Gateworks SBCs provide the computational power and flexibility needed to integrate with various automation systems, from programmable logic controllers (PLCs) to robotic arms. Paired with Wi-Fi, cellular, Bluetooth etc. they enable real-time communication and seamless connectivity across a smart factory, ensuring continuous performance optimization. This ensures that automation systems can respond to real-time data, adapt to changing conditions, and optimize performance continuously.

MACHINE HEALTH

Proactively Maintain Equipment with Real-Time Monitoring

Paired with high-precision sensors and connectivity modules, Gateworks SBCs can collect and analyze data on temperature, vibration, and other critical parameters to ensure optimal performance of industrial equipment. By utilizing machine learning algorithms, one can predict potential failures before they occur, allowing for preemptive maintenance. This not only reduces downtime but also extends the lifespan of machinery, saving time and resources.

WIRELESS SENSOR NETWORKS

Collect and Process Data on the Edge Seamlessly

Gateworks SBCs act as central hubs for real-time edge computing, collecting and processing data from wireless sensors monitoring environmental conditions, equipment or production output. Combined with IoT modules, these systems ensure peak operational efficiency and instant data access.

SAFETY SYSTEMS

Prioritize Workplace Safety with Intelligent Monitoring Systems

Integrated with emergency stop systems, gas detectors, and access control devices, Gateworks SBCs trigger automated responses at the edge to hazardous conditions. By leveraging wireless connectivity, safety systems can communicate instantly across large facilities to ensure every worker and process is protected at all times.

ROBOTICS

Empower Precision and Control in Robotics

The computational power needed to control robotic systems, from simple pick-and-place arms to complex autonomous mobile robots (AMRs) can be managed by a Gateworks SBC. When integrated with high-speed networking and real-time edge processing, robots can be enabled to operate with precise control, adapt to dynamic environments and execute tasks with minimal latency. This level of integration makes it possible to scale robotic operations across various industrial applications.

NETWORKING

Build a Reliable, Scalable Network for Operations

A strong network is the foundation of any smart factory, enabling all devices, sensors, and systems to communicate effectively. Gateworks SBCs are designed to serve as central nodes in these networks, providing high-speed connectivity through wired and wireless options. By leveraging modules for Wi-Fi, cellular, and Ethernet connectivity, factories can ensure all systems are interconnected, data is transmitted securely and operations remain synchronized.

ASSET TRACKING

Keep Track of Assets with Precision and Ease

A Gateworks SBC, combined with GPS and wireless communication modules, offer comprehensive asset-tracking solutions for complex industrial efficiency. Whether tracking the location of mobile equipment, inventory, or even personnel, SBCs can provide real-time data that ensures assets are always where they need to be. This visibility helps in optimizing workflows, reducing losses and improving overall resource management within a smart factory.

RECOMMENDED PRODUCTS

We recommend the following products designed to deliver robust performance, seamless connectivity and tailored functionality for a wide range of industrial IoT applications.

GW8200 VeniceFLEX SBC

✓ High-Performance Low Power ARM® SBC

✓ NXP™ i.MX 8M Plus

✓ CE-Ready

✓ Linux OS & Board Support Package

✓ Isolated CAN & PoE

✓ 2x Gigabit Ethernet Ports

✓ 2x Flexible Sockets

Wi-Fi HaLow

✓ 802.11ah HaLow Low-Power, Long-Range Wireless

✓ Silex SX-SDMAH 802.11ah Module

✓ Frequency: 903.5 ~ 926.5 MHz

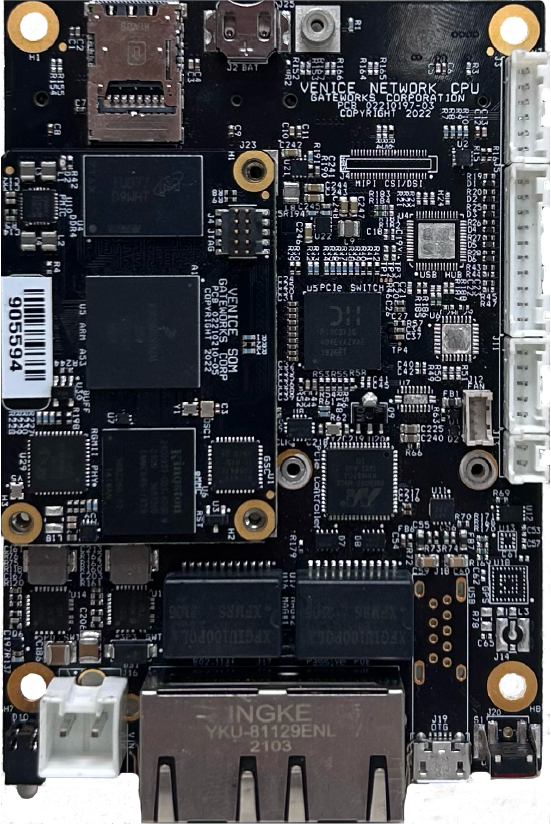

GW7200 Venice SBC

✓ High-Performance Low Power ARM® SBC

✓ NXP™ i.MX 8M Mini or Plus

✓ Linux OS & Board Support Package

✓ 2x Gigabit Ethernet Ports

✓ 2x Mini-PCIe Slots

✓ RS232, RS485,

Wi-Fi HaLow

✓ 802.11ah HaLow Low-Power, Long-Range Wireless

✓ Silex SX-NEWAH 802.11ah Module

✓ Frequency: 902.0 ~ 928.0 MHz

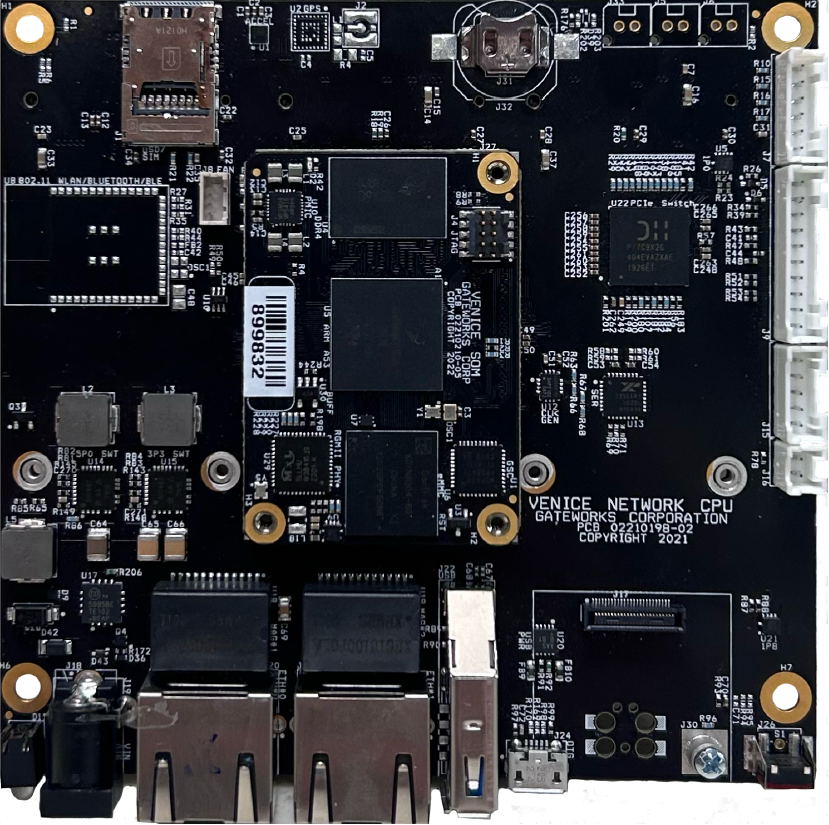

GW7300 Venice SBC

✓ High-Performance Low Power ARM® SBC

✓ NXP™ i.MX 8M Mini or Plus

✓ Linux OS & Board Support Package

✓ 2x Gigabit Ethernet Ports

✓ 3x Mini-PCIe Slots

✓ RS232, RS485,

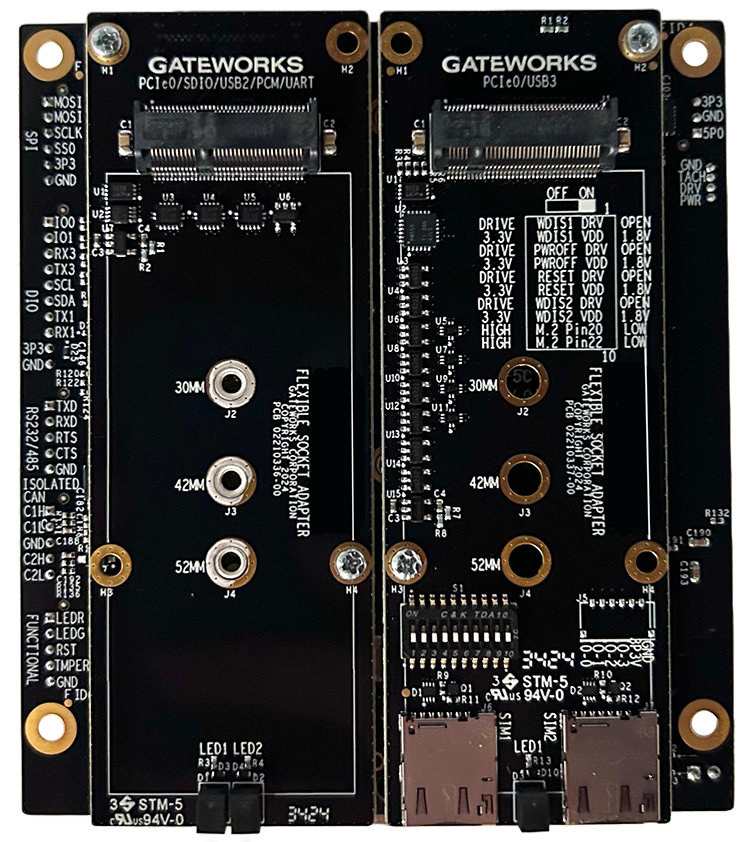

Mini PCIe to M.2 Adapter for Cellular Modems

✓ Converts Mini-PCIe slot to M.2 B-Key Slot for 5G Cellular Modems & Other M.2 Cards

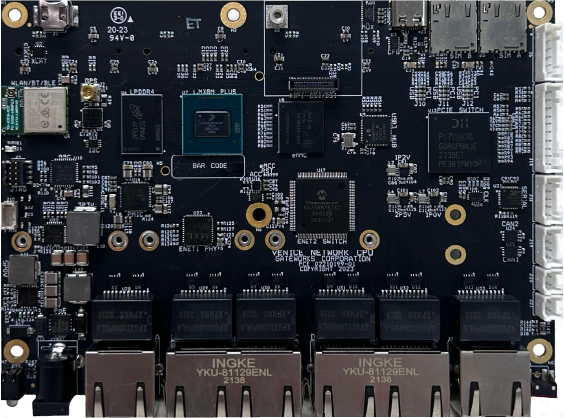

GW7400 Venice SBC

✓ High-Performance Low Power ARM® SBC

✓ NXP™ i.MX 8M Plus

✓ Linux OS and Board Support Package

✓ 1x Gigabit Ethernet Ports

✓ 3x Mini-PCIe Slots

✓ 1x M.2 Slot

✓ CAN

Cellular & BLE

✓ u-blox SARA-R410M-02B LTE CATM1 Cellular Modem

✓ u-blox NINA-B301 Open CPU Bluetooth 5.0

✓ Low Cost, Low Bandwidth