MADE IN THE USA, ENGINEERED FOR RELIABILITY

Transparent Manufacturing. Exceptional Quality. Built in SLO, California.

At Gateworks Corporation, we believe quality begins at our own state-of-the-art facility in San Luis Obispo, California. From PCB assembly through final functional test, every board is built under one roof, with full traceability, real-time process monitoring and complete visibility into our workflow. Because when you’re designing systems that must keep running in demanding environments, you need more than a product, you need confidence in every step of how it was made.

MANUFACTURING CAPABILITY

Gateworks manufactures all of its printed circuit board assemblies (PCBAs) in a 6,200 sq ft state-of-the-art facility adjacent to the corporate office in San Luis Obispo, California.

Using highly automated machines and specialized control software capable of placing 18 million components a month, the manufacturing capability is 38,000 PCBAs per month.

A secondary benefit of having the manufacturing capability on-site is that special configurations of a product, custom designs, and small prototype builds can be done much quicker than when sent to an offshore facility or contract manufacturer.

The assembly facility is environmentally friendly, using an Aqueous Technologies closed-loop wash system and 100% RoHS lead-free solder. Each step of the production process, including final functional testing, is captured and monitored in a proprietary process management and ERP system.

PRECISION AUTOMATED ASSEMBLY

Advanced equipment, controlled processes, and real-time data ensure consistent quality from solder paste to final test.

Gateworks relies on advanced automated processes to ensure consistent, high-quality production across every board built in our California facility. Automated laser stencil printing delivers accurate solder paste application, reducing component-level defects. High-speed SMT machinery supports broad component flexibility, including large BGAs, fine-pitch micro BGAs, 0402 chips, and odd-form parts. A controlled multi-zone reflow process creates solid, reliable solder joints, while selective soldering provides precise and repeatable through-hole connections.

Our automated cleaning system removes flux residue and contaminants, and our paperless, computer-controlled workflow ensures all product documentation is accurate and available in real time. Automated optical inspection (AOI) and image recording validate quality at each step, supported by full functional testing with logged results. All equipment communicates with our ERP system to deliver real-time process metrics and receives scheduled preventative maintenance to minimize downtime and defects.

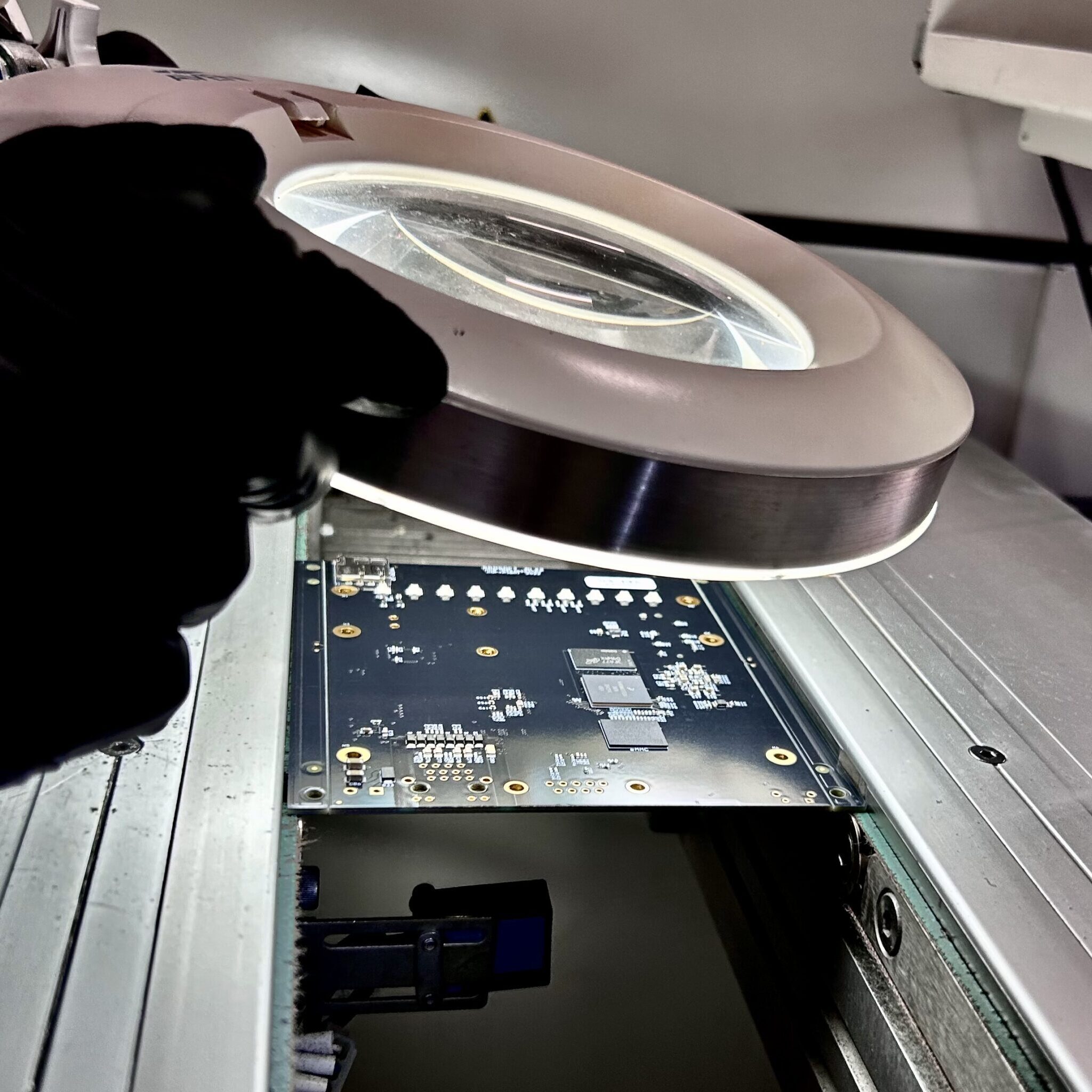

SKILLED TECHNICIANS & RIGOROUS QUALITY CONTROL

Certified personnel, structured inspections and strict standards drive reliability across every build.

Beyond automation, Gateworks maintains strict quality standards enforced by highly trained personnel. We build to IPC-A-610 Class 2 standards, and our IPC-certified technicians receive ongoing recurrent training to maintain alignment with the latest industry best practices. Non-automated processes pause every 40 minutes for mandatory QA inspections, ensuring any potential issues are caught early.

Our commitment to quality extends to every corner of the operation: routine equipment inspections, documented testing, and continuous investment in people, equipment, and processes ensure the reliability of today’s products and the readiness for tomorrow’s demand.

INTEGRATED PROCRESS CONTROL

End-to-End Product Documentation and Development

A unified system that captures every engineering detail and ensures consistent, repeatable builds.

Product development originates with documents and follows an approval process, all of which are recorded in the system: product requirements, schematics, layouts, bills of materials, and assembly drawings. The associated manufacturing process documents are also constructed and maintained in the system, from the originating documents, to ensure the accurate and consistent assembly of products over time.

The entire supply chain process is managed in the system, from product demand to inventory levels, material requisition, receiving components, and placement on product. Every component has a barcode associated with it, allowing traceability back to the point of origin and supplier.

INTEGRATED PROCRESS CONTROL

Full Manufacturing Traceability and Real-Time Quality Enforcement

Complete product history from SMT placement to repairs is captured, tracked, and validated.

End products produced at Gateworks are uniquely identified with a barcode serial number to track the product through the manufacturing process, from SMT placement to final packaging and shipping. Relevant information from every step in the process is captured, including test configurations, programmed flash images, test results and timestamps. The system does not allow a product to be shipped until every process is complete and approved.

If a product is returned for repair, its original manufacturing history is available to aid with troubleshooting; any repair work and subsequent testing is captured and added to the product history.

BUILT BETTER THROUGH INTEGRATED DESIGN & PRODUCTION

Our co-located teams work side by side sharing insights, refining designs, and optimizing testing to deliver rugged, reliable hardware built for long-term performance.

A key differentiator of Gateworks products is that they are designed and manufactured together at the corporate headquarters in California. Creating everything at one location allows for close collaboration and communication between design, manufacturing, and support team members. Board designers receive feedback from support and manufacturing during new product design reviews allowing constant improvement of quality and manufacturability. Manufacturing engineers benefit from the ability to sit with a designer to discuss testing procedures and potential high risk areas before a design is released.