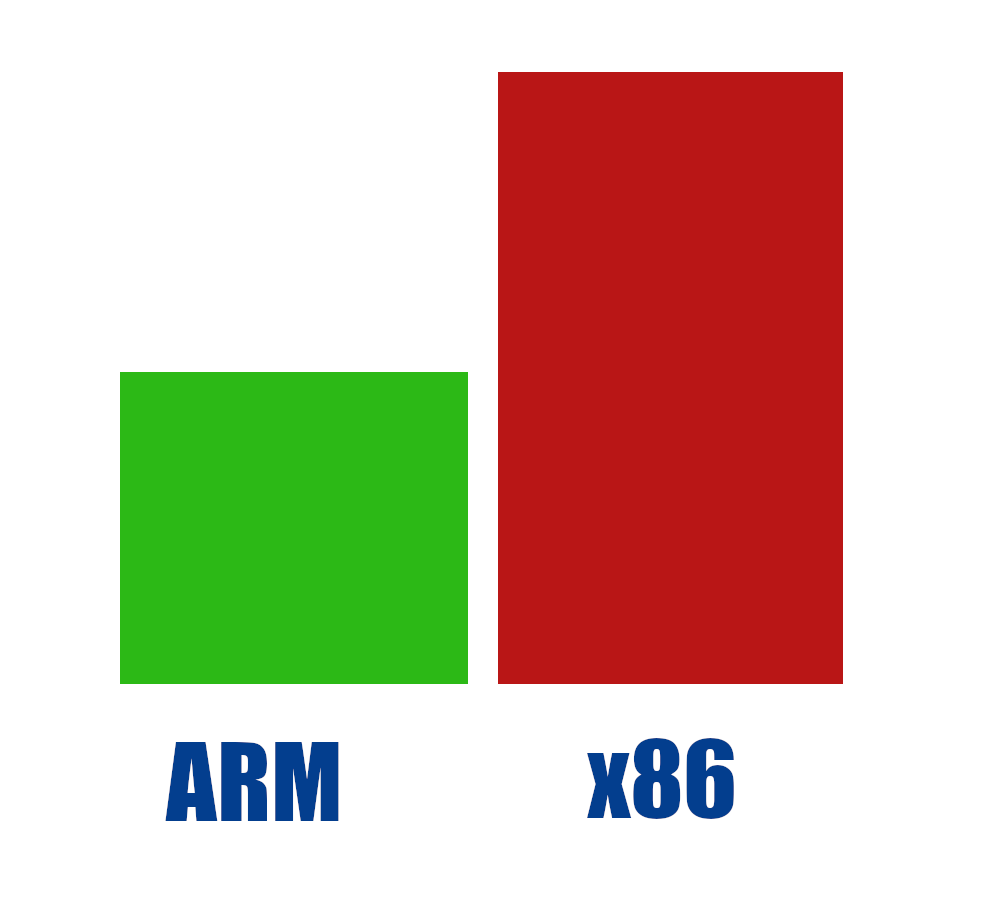

Embedded single board computers (SBCs), such as the Gateworks family of Industrial Single Board Computers, are used in nearly every rugged and industrial application around the world. As technology and automation are implemented into all sectors, tasks and processes become easier, more automated and more efficient. The brain behind all this is the CPU (Central Processing Unit) or SoC (System on Chip). The top two architectures are x86 and ARM. While x86 has traditionally been better suited towards desktop and server applications, there has been a recent push into the embedded market. While the x86 has made some fair strides, there are still reasons why the ARM architecture is excelling in embedded rugged & industrial single board computers.

1. Power Savings

ARM processors have long been known to be the leader in low power devices in embedded industrial applications. Only recently has x86 started to make an attempt at scaling down their power usage for markets where low power is important. While they have made some progress, the ARM CPUs still reign king. Often the X86 CPUs will have an excess of peripherals that are unused, thus driving up the amount of watts consumed unnecessarily. For example, on a common x86 embedded processor the TDP (total dissipated power) for the CPU only is rated at 4.5-12W whereas a comparable ARM is rated at 9mW (suspend) to 2.3W under stress. Power is always somewhat ambiguous because there are so many variables, but if there is going to be one processor architecture that has the best potential, it would be ARM.

2. Cost Savings

In general, ARM CPUs are likely to be more cost effective due to a smaller feature set that is often adequate for most industrial embedded applications. It has been mentioned that x86 processors typically will have more features than needed in an embedded application, such as multiple PCIe lanes or multiple GbE interfaces. While impressive, these often aren’t used and thus not worth the extra cost. Typical volumes of ARM SoC production have been driven up due to the massive demand from the mobile and embedded market. Mass production usually brings more efficient build processes which turns into a lower price. ARM licenses out it’s technology and thus multiple competitors stand to build the best ARM chips. More competition means stronger price wars, thus lessening the chance of any price hungry monopoly.

3. Space Savings

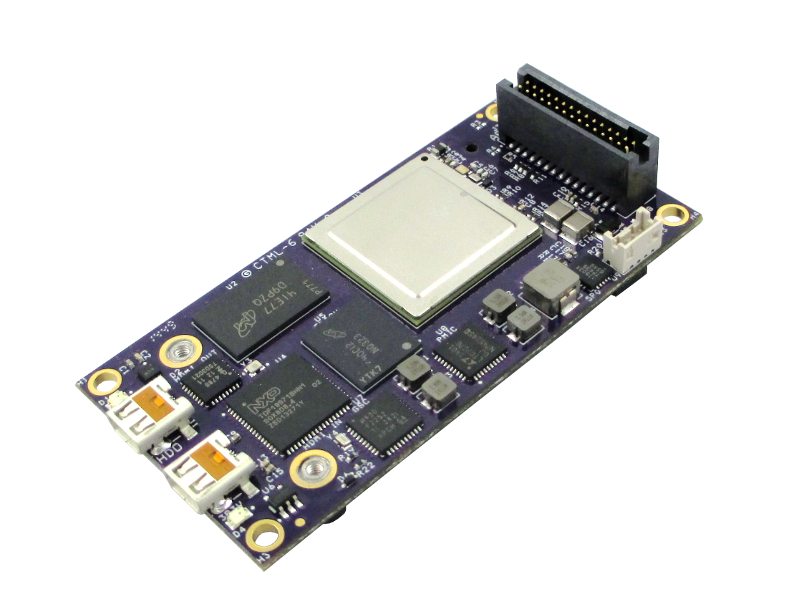

The ARM architecture allows for substantial savings in overall size. Often, embedded applications require the smallest form factor for the least amount of impact on the surrounding system. For example, the Intel Elkhart has a package size of 35x24mm where the NXP i.MX8M Mini is 14x14mm. This reduction in size allows for a much smaller overall board size. Consumers have become accustomed to a shrinking of overall device sizes and at times it is mandatory. Imagine scenarios where weight and size is of the utmost importance, such as on a drone or inside a piece of oil equipment. Additionally, the larger power usage of an x86 processor would typically require a larger thermal solution (heatsink/fansink) which contributes to the overall solution size. It is obvious when a small and highly advanced piece of technology, such as an Apple iPhone, uses an ARM processor, that ARM is the architecture of choice when space is of the utmost importance. The smallest Gateworks Rugged and Industrial SBC is the Ventana GW5510 measuring a mere 35x70mm.

4. Software Options

One of the most common operating systems in embedded industrial and rugged applications is some form of Linux. Linux does run on x86, but it is important to note it is also fully supported on the ARM architecture. Linux can be scaled down to be very lightweight and flexible to adapt to nearly any demand. This scaling allows performance boosts and reduced loading times for sensitive applications. Linux is open source and thus the user has full control of the operating system and software. Gone are the black holes of proprietary code. Anything and everything can be adjusted as the user sees fit. A large open source community has produced a plethora of packages and applications that easily load on an operating system such as Ubuntu. Rather than relying on a single company for software, users can cumulatively create masterpieces in the open source realm.

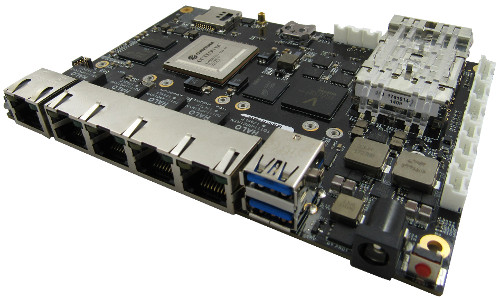

It is clear that for rugged and industrial embedded applications, ARM processors are a staple platform that excels in the given conditions. Gateworks Corporation designs and manufactures ARM based single board computers in the USA. Several board families have varying sizes from 35x70mm up to 140x100mm. The SBCs feature multiple ethernet (including dual Gigabit) ports as well as multiple Mini-PCIe slots for WiFi and Cellular radios. Each board is designed with an optimized and highly efficient power supply that accepts 10-60VDC. To view the entire line of Gateworks SBCs, please visit the Gateworks Industrial Single Board Computer product page.